For nearly half a century, mirrors have been our ultimate fascination. It is probably for this very reason that the FLEXMIRROR® brand, formerly Alluvial®, is synonymous with the largest, most transparent, most brilliant and distortion-free mirror image in the world.

At the same time, our top priority is to not only maintain the standard, but to continuously refine it to not only meet the demands of our clients in terms of quality, but also to meet our own.

Mit unserer eigenen Eindampf- und Schneidanlage wird das Rohmaterial in unserem Hauptwerk in der Nähe von München/Deutschland hergestellt. Derzeit veredeln wir unsere FLEXMIRROR®-Produkte an 30 Produktionsstandorten weltweit.

Dadurch sind wir in der Lage, FLEXMIRROR®-Produkte für unsere Kunden an nahezu jedem Ort der Welt mit äußerst kurzen Lieferwegen herzustellen, ohne dass das erforderliche Material, die Ausrüstung und das Personal rund um den Globus transportiert werden müssen.

Sollte der Spiegel für eine Lieferung zu groß sein, steht Ihnen unser mobiles Produktionsequipment zur Verfügung und wir fahren einfach direkt zum Montageort.

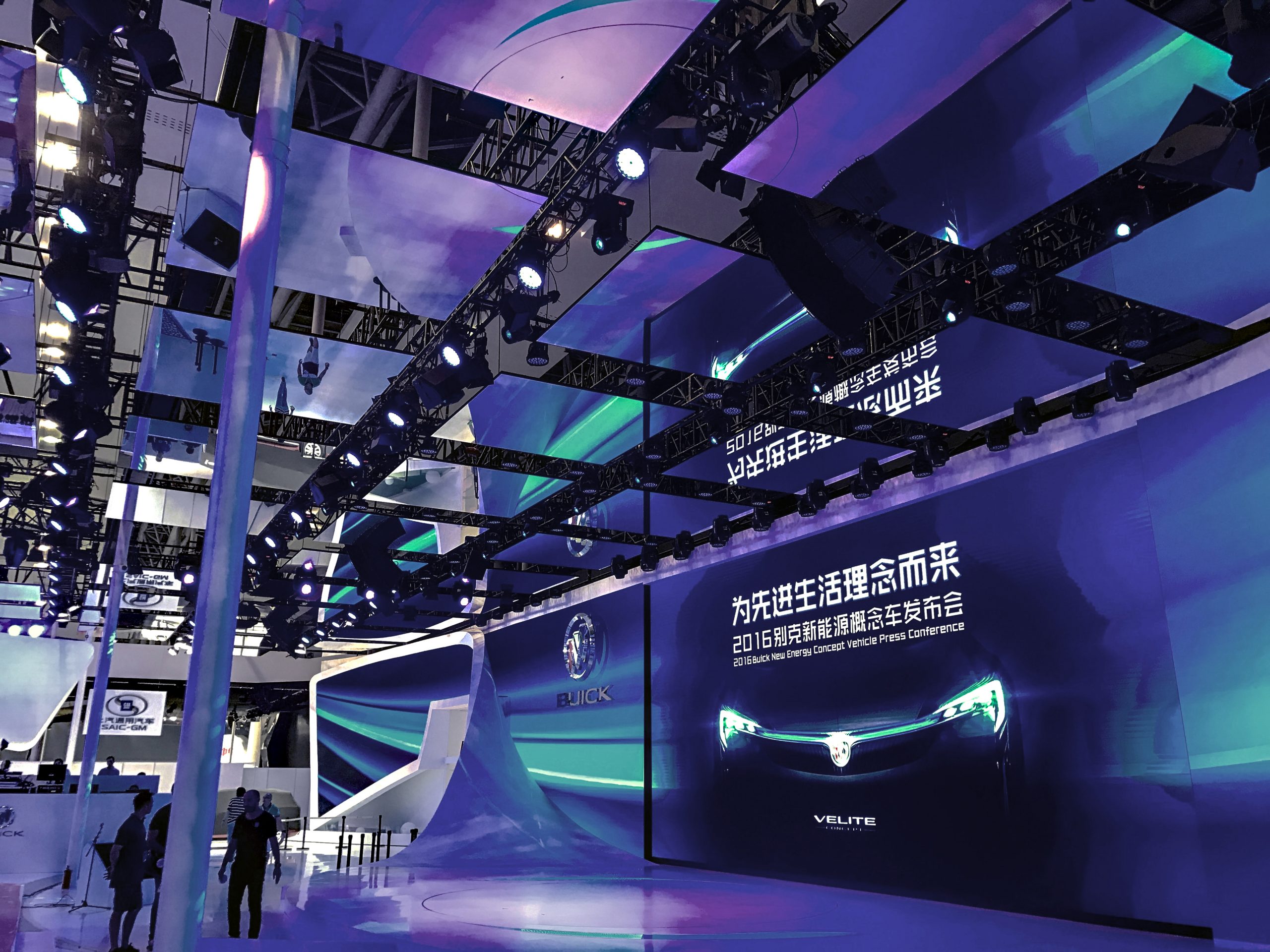

There’s probably nothing better than seeing a completed customer project so impressive that it takes your breath away? We still feel that way after all these years. That’s why, with each mirror project, we endeavour to give our customers our best possible support and to work with them to find the ideal solution for their project.

In most cases, the project begins at a very early stage with the conception, dividing of the surfaces and placing of the substructure. It only ends after the installation has been implemented to perfection.

Our love of the art of installation has often pushed us to the limits of the possible and ultimately allowed us to grow well beyond. We owe special thanks to the artist „Olafur Eliasson“ and his team. FLEXMIRROR® would never be where it is today – where the job is more than just a vocation – without Olafur’s visions and projects.